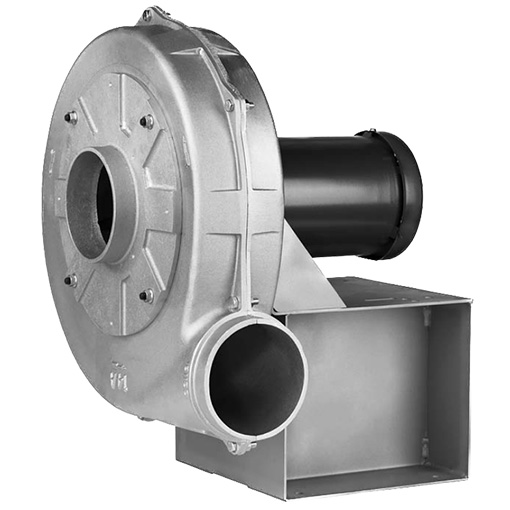

High Pressure Blower

High-pressure blowers are powerful devices designed to generate a strong, concentrated airflow at significantly higher pressures than standard fans or blowers. These blowers are used in applications that require the movement of air or gasses against substantial resistance, such as in pneumatic conveying systems, combustion air supply, and industrial processes like drying, cooling, and aeration.

High-pressure blowers typically feature robust construction and specialized impeller designs that allow them to maintain performance under demanding conditions. Their ability to deliver high-pressure airflow makes them essential in industries like manufacturing, chemical processing, and wastewater treatment, where precise air movement and control are critical.

- CFM Capacities: Up to 50,000 CFM

- Static Pressure: Up to 100 inches W.G.

- Temp Range: Up to 2000°F for high-temperature applications

- Fan Size: 8” to 48”

- Material Type: Aluminum, Carbon Steel, Mild Steel, Stainless Steel, FRP

- HARTZELL

- CINCINNATI FAN

- IAP

- PDF DOWNLOADS

| Model | Type | Material | Airflow | Static Pressure |

|---|---|---|---|---|

| Series 04 | High Pressure Backward Curved Centrifugal Fan | Steel, 304SS, 316SS, AMCA A, B, C | Up to 75,000 CFM | Up to 16 in. WG |

| Series 05/05F | Backward Inclined Industrial Exhauster Centrifugal Fan, Flanged Mount Type Available | Steel, 304SS, 316SS, AMCA A, B, C | Up to 46,000 CFM | Up to 46 in. WG |

| Series 07/07T/07M | Backward Inclined Pressure Blower, Turbo and Marine Duty available | Steel, Aluminum, 304SS, 316SS, AMCA A, B, C, Hot Dipped Galvanized | Up to 5,250 CFM | Up to 60 in. WG |

| Series 42 | Fiberglass Pressure Blower | Fiberglass | Up to 1,500 CFM | Up to 12” WG |

| Series 40 | Fiberglass In-line Centrifugal Fan | Fiberglass | Up to 90,000 CFM | Up To 12” W.G. |

Please contact us for details on our full backward curved fan selection, additional models are available!

| Model | Type | Material | Airflow | Static Pressure |

|---|---|---|---|---|

| Model PB | Cast Aluminum Pressure Blower | Cast Aluminum housing and wheel (standard) | 50 to 5,000 CFM | Up to 100 in. WG |

| Model PBS | Fabricated Steel Pressure Blower | Fabricated Carbon Steel; Optional: Stainless Steel or coated steel | 100 to 12,000 CFM | Up to 100 in. WG |

| Model SPB | Pressure Blower, Die-Formed Steel | Die-Formed Steel | 350 to 25,000 CFM | Up to 20 in. WG |

Please contact us for details on our full backward curved fan selection, additional models are available!

| Model | Type | Material | Airflow | Static Pressure |

|---|---|---|---|---|

| Backward Inclined, Type B | Backward Inclined Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 500 to 100,000 CFM | Up to 12 in. WG |

| Backward Curved, Type XBC | Backward Curved Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 1,000 to 95,000 CFM | Up to 13 in. WG |

| Airfoil, Type A | Airfoil Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 1,200 to 110,000 CFM | Up to 15 in. WG |

| Open Radial Blade, Type ORB | Open Radial Blade Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 600 to 90,000 CFM | Up to 18 in. WG |

| Modified Radial Tip, Type P | Modified Radial Tip Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 700 to 85,000 CFM | Up to 17 in. WG |

| Wool Trip, Type WT | Wool Trip Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 800 to 95,000 CFM | Up to 16 in. WG |

| Radial Tip, Type XRT | Radial Tip Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 900 to 105,000 CFM | Up to 18 in. WG |

| High Pressure, Type HP | High Pressure Centrifugal Fan | Carbon Steel, Stainless Steel, Aluminum | 500 to 60,000 CFM | Up to 22 in. WG |

| High Pressure Blower, Type HPB | High Pressure Blower | Carbon Steel, Stainless Steel, Aluminum | 300 to 40,000 CFM | Up to 25 in. WG |

Please contact us for details on our full backward curved fan selection, additional models are available!

Things to Consider When Buying High Pressure Blowers

Several things should be considered when purchasing high-pressure blowers in order to achieve optimal performance and efficiency. Consider the required airflow and pressure specifications for your application to specify the right the blower capacity. Energy efficiency is another important aspect, as blowers can be energy-intensive, so selecting models with higher efficiency ratings can lead to long-term cost savings. Additionally, consider the material construction for durability, especially if the blower will handle corrosive or abrasive substances. Noise levels, ease of maintenance, and compatibility with your existing systems should also be considered to ensure smooth integration and optimal operation.

J.E. Phillips Company Serves High Pressure Blowers Application Needs

J.E. Phillips Company serves a variety of industries with high pressure blowers designed to meet specific needs. We are proud to partner with Hartzell, Cincinnati Fan, IAP, Daniels Fans to offer high pressure blowers in configurations to meet a wide array of application needs.